Our chemical engineers, experts in the development of finishes for industrial applications, work hand in hand with our customers in our laboratories located in France and Belgium. Thanks to industrial tests, our technical sales representatives guide and train line operators in the proper use of our products on equipment, with the aim of constantly seeking to improve quality and optimize production costs.

They are in close contact with the industrial customers, which allows a more global and quicker consideration of the specifications as well as the production requirements. These experts are the most efficient interlocutors to define the technical environment in which the solution will be developed and applied.

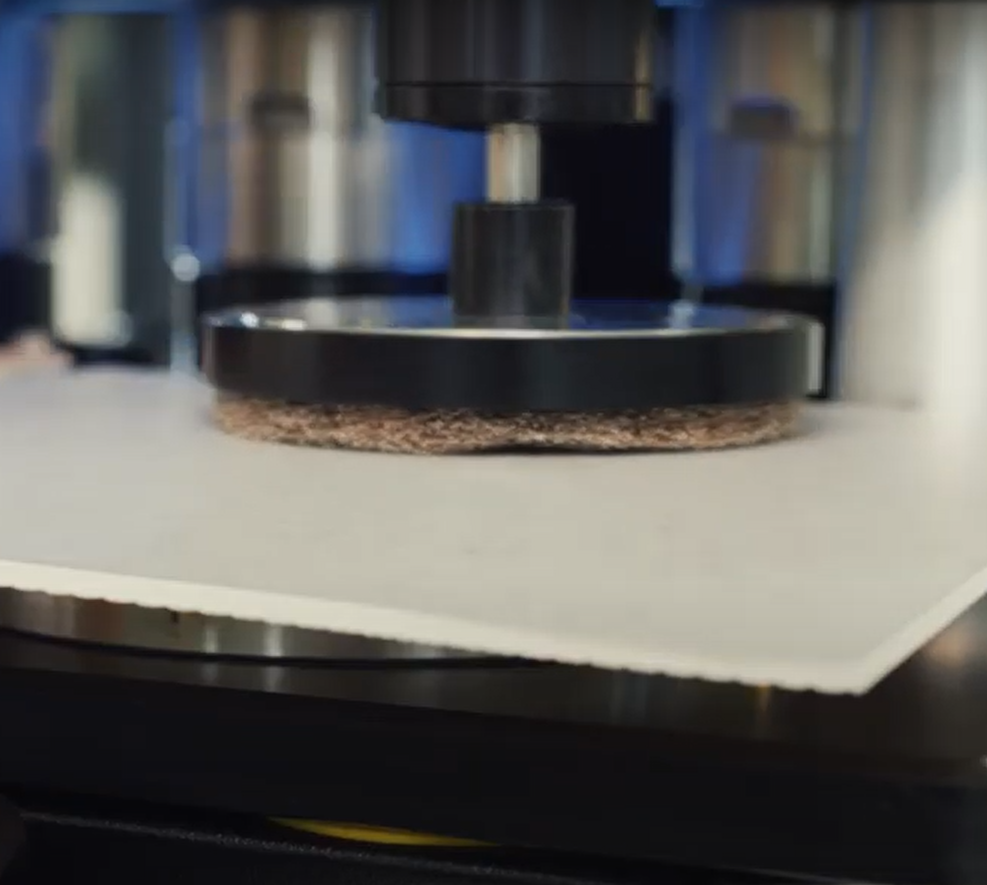

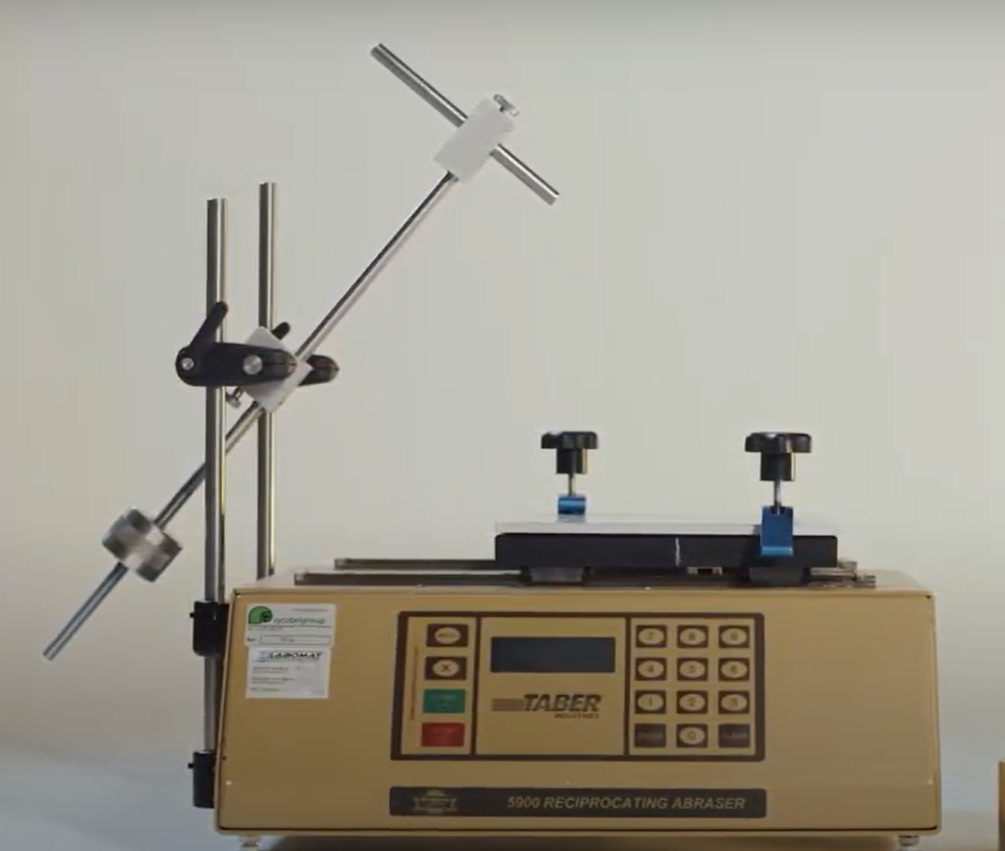

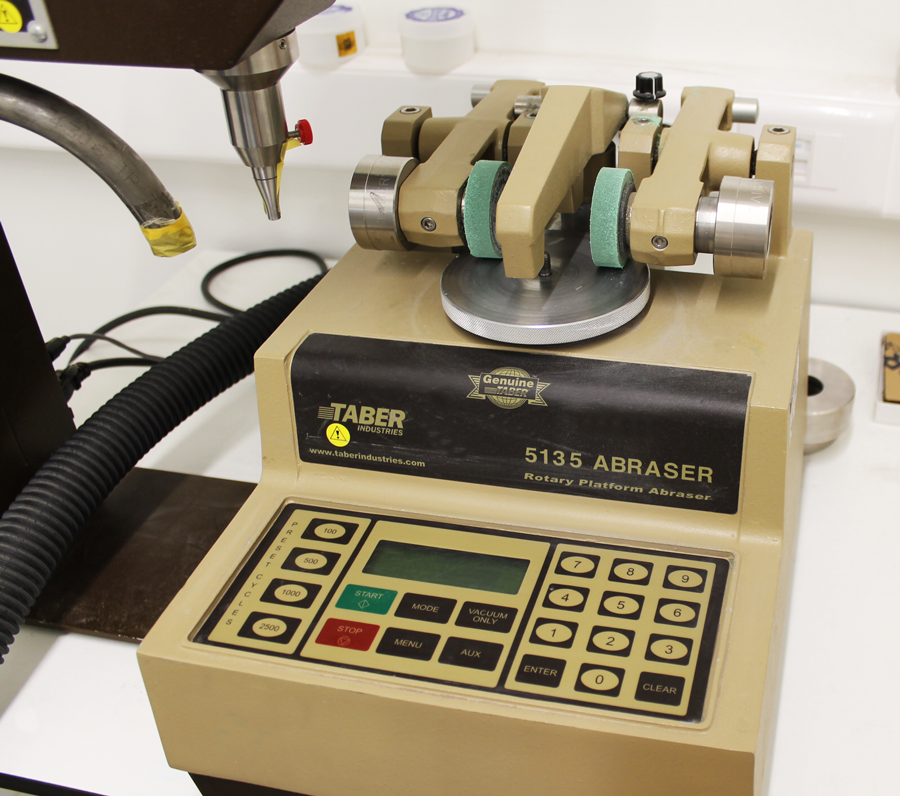

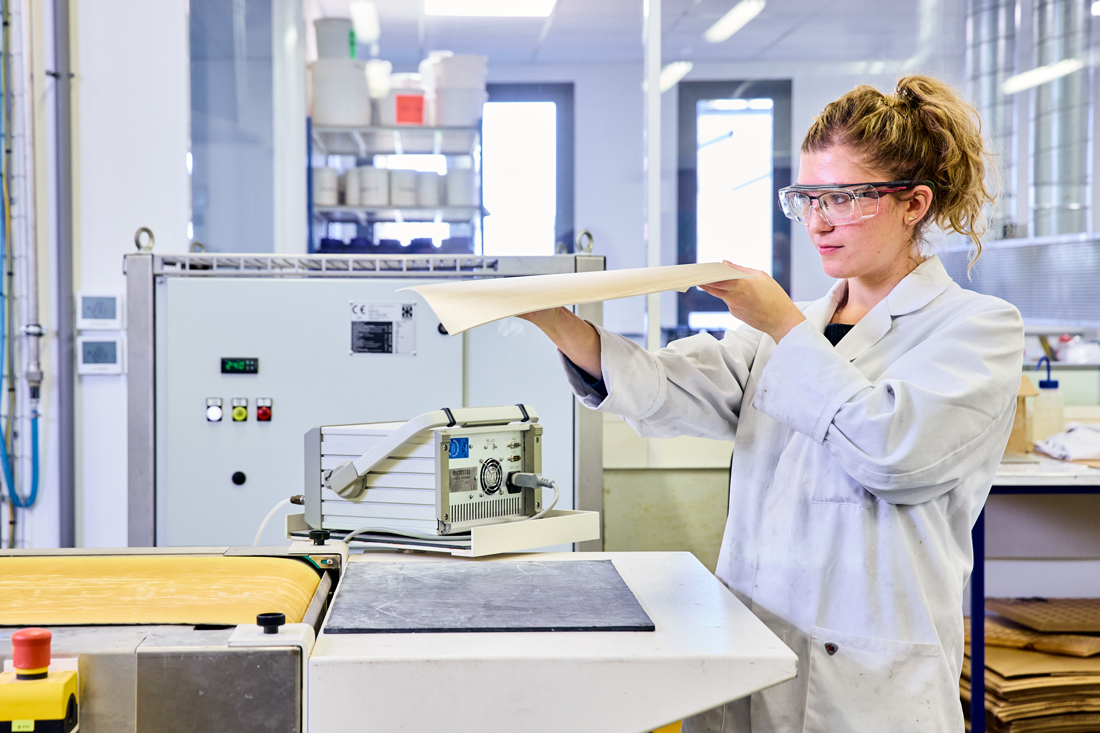

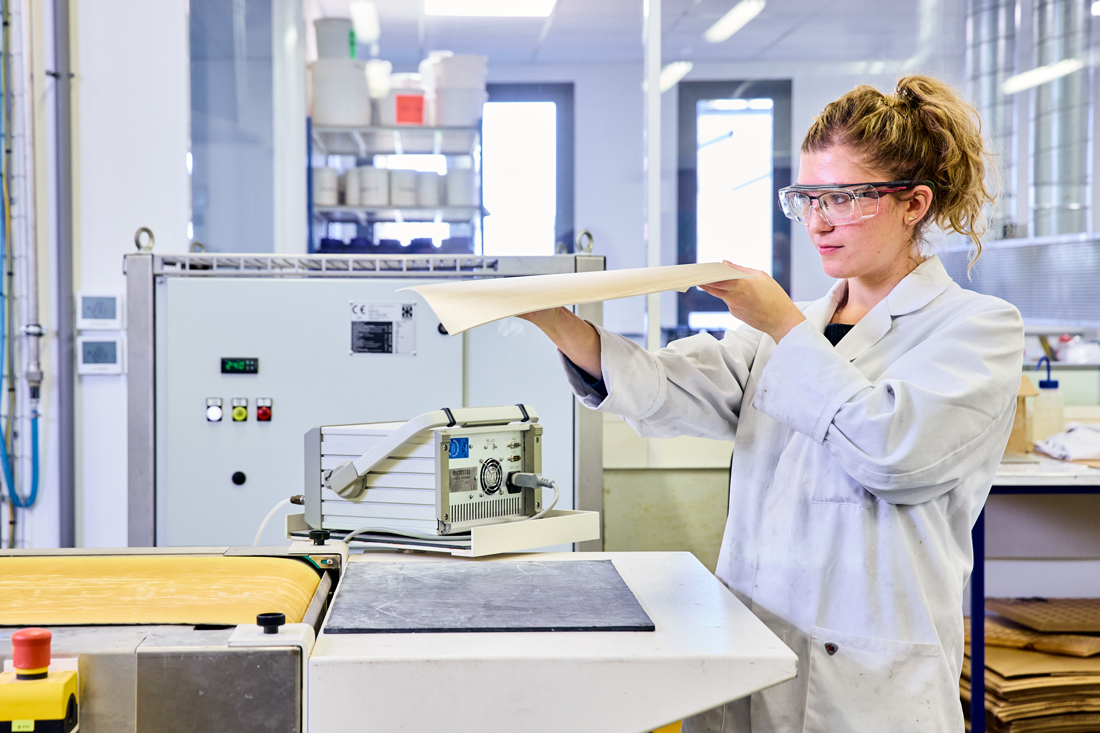

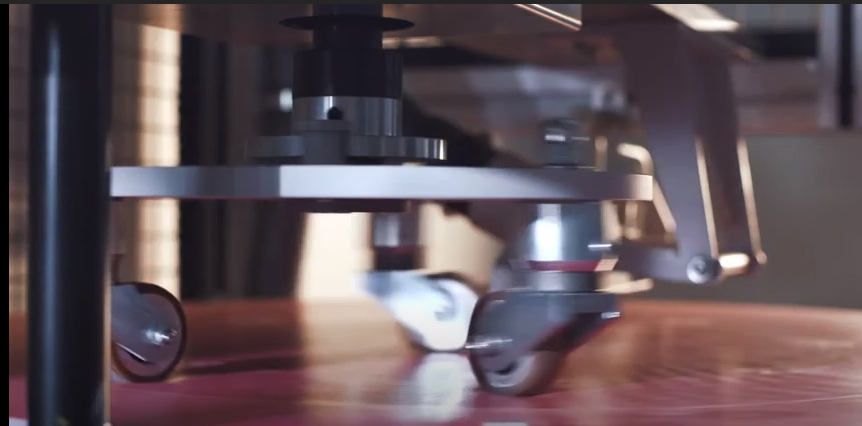

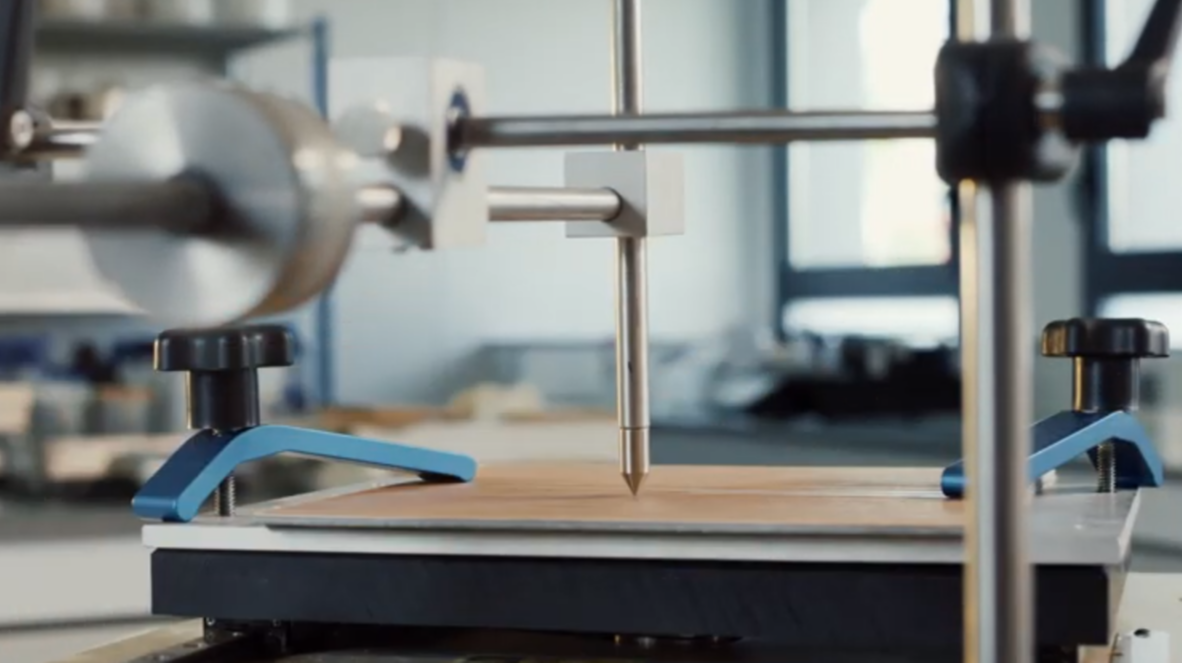

In order to offer high-performance technologies that are fully tailored to the customer's specifications, our teams put all their innovations and formulations through standardized laboratory tests. Demanding processes, guarantees of performance, the Blanchon Industry signature.

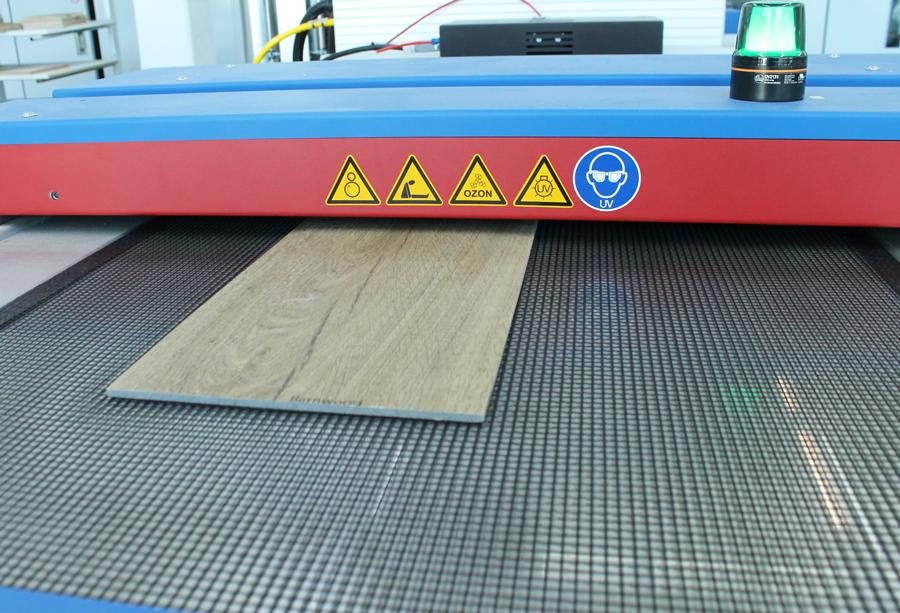

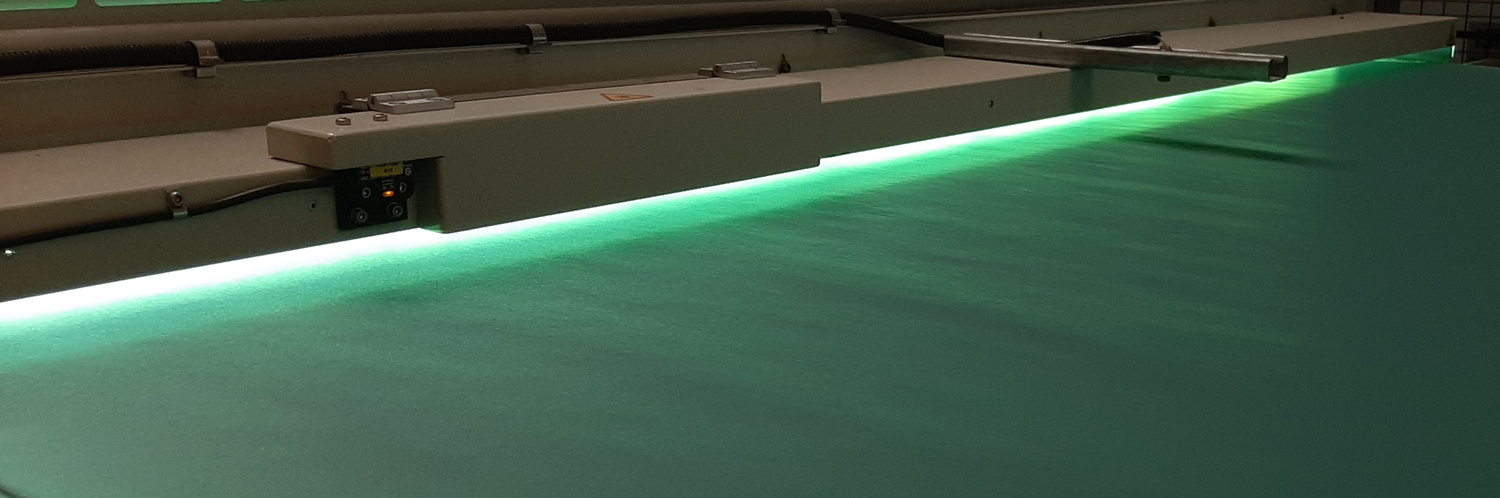

Located in Saint-Priest (France) and Roeselare (Belgium), our engineers design tailor-made solutions to meet our customers' specifications. We develop solutions adapted to the setup of their UV coating line.

Our equipment features the performance of the developed solutions. The evaluation of the finished products is always carried out with samples applied on the machines of the industrial laboratory corresponding to those of the industrial lines.